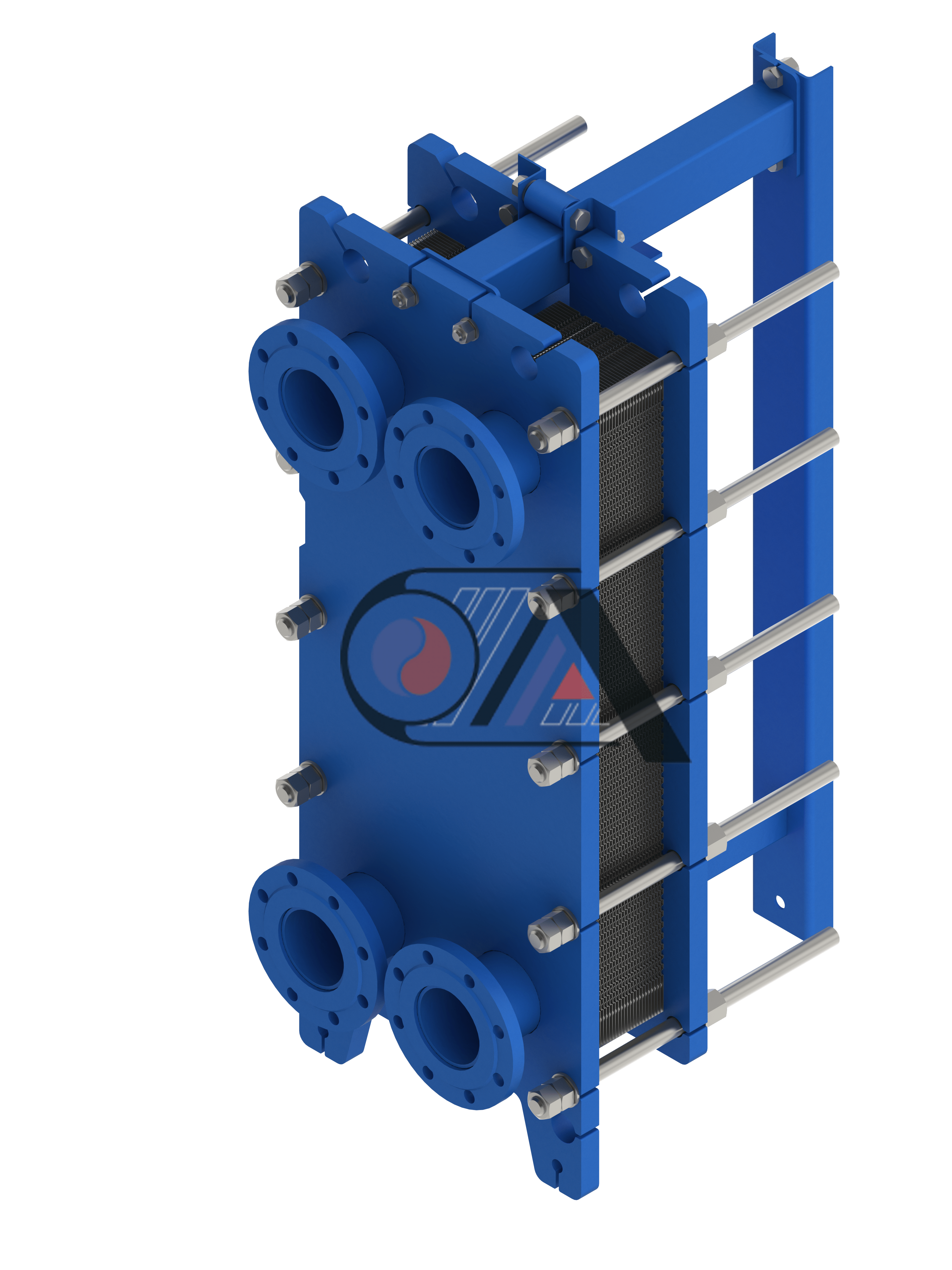

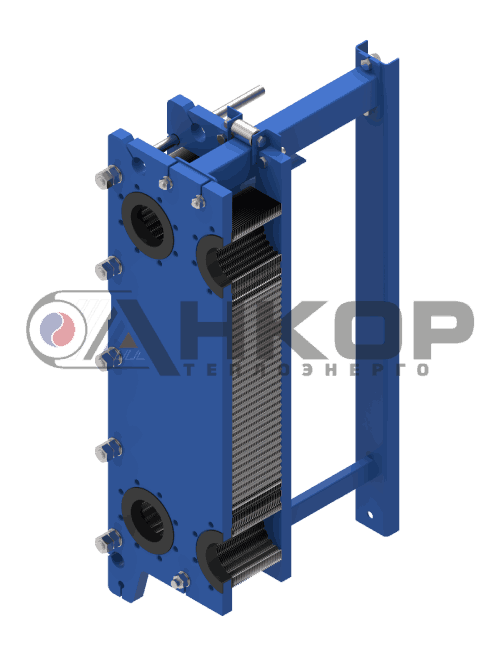

Criss-cross heat exchangers

Criss-cross heat exchangers are devices with a complex channel shape, which allows turbulize a flow and significantly increase equipment efficiency.

Criss-cross heat exchangers manufactured by Ankor-Teploenergo include the main types of the plate ones: classic gasketed, brazed, welded and with removable shell.

The characteristics describing the criss-cross plates of the heat exchanger include the following indicators: angle of the corrugation inclination, channel height and the method of channel formation.

Different angle of the corrugation inclination is typical for the gasketed devices. Options are possible with the use of plates with corrugation angle from 30° to 120°. This indicator affects the heat transfer efficiency and head suppression. If the angle is 30°, the losses will be minimal, but at the same time, the efficiency will also be minimal. As the angle increases, the pressure loss will increase, but the efficiency will also increase.

Technical specifications of the criss-cross heat exchanger

| RANGE OF APPLICATION OF GASKETED PLATE HEAT EXCHANGER: | VALUE (CHARACTERISTIC) |

| Maximum operating temperature: | from -30 to +200 °С |

| Maximum pressure: | 2.5 MPa |

| Area range: | from 0,18 to 1800 m² |

| Thermal load | 150 Mw |

| Plate materials: | AISI 304 AISI 316 Hastelloy С-276 SMO 254 Titanium Nickel 200 |

Advantages of the criss-cross heat exchanger

The main advantage may be considered efficiency. Indeed, due to the complex geometry of plates, the flows in such equipment are turbilized and the heat exchange process occurs more intensively.

Hence, as a result, a smaller surface area, dimensions, and weight are required.

In addition, the cost of products is significantly reduced. This allows such heat exchangers to compete adequately with other types of heat exchange equipment, for example, tubular one.

Technical specifications of the criss-cross heat exchanger

Criss-cross heat exchangers manufactured by Ankor-Teploenergo include the main types of the plate ones: classic gasketed, brazed, welded and with removable shell. The corrugations of plates of such products form channels of complex shape, with a varying height along the entire length of the plate. In fact, this complex shape may be called a wave.

The characteristics describing the criss-cross plates of the heat exchanger include the following indicators: angle of the corrugation inclination, channel height and the method of channel formation.

Different angle of the corrugation inclination is typical for the gasketed devices. Options are possible with the use of plates with corrugation angle from 30° to 120°. This indicator affects the heat transfer efficiency and head suppression. If the angle is 30°, the losses will be minimal, but at the same time, the efficiency will also be minimal. As the angle increases, the pressure loss will increase, but the efficiency will also increase.

In conventional devices, a channel is formed of two plates. In other words, in fact, the height of channel is the height of corrugation of the two plates together. This value can vary in all types of criss-cross heat exchangers. It mainly affects the flow rate and, as a consequence, the heat transfer rate and pressure loss. The lower the height, the greater the speed, the more efficient the plate. However, head losses due to this will increase. On the other hand, the higher the corrugation, the more slowly flows the stream. This means that the pressure drop will be lower.

There are essentially three methods of formation: using gaskets, brazing alloy or welding. Gaskets mainly relate to the gasketed units. In the welded heat exchangers, plates are welded together around the perimeter, forming sections. Then they are welded along the collector hole and form a pack. Brazing is used in the manufacture of brazed devices.

Order Online Presentation

Our employee will contact you to coordinate the timing of the presentation

How the price for the criss-cross heat exchanger is calculated

First of all, to determine the cost, it is necessary to calculate the criss-cross heat exchanger and determine its type. Next, the optimal area and geometry are chosen, a list of materials is compiled, labor costs are estimated.

It is possible to buy a criss-cross heat exchanger of any type after determination of the purpose and further calculation.

Fields of application criss-cross heat exchanger

Fields of application will be identical to the gasketed, brazed and welded devices. After all, it is these devices that represent the class of criss-cross heat exchangers.

Criss-cross heat exchangers