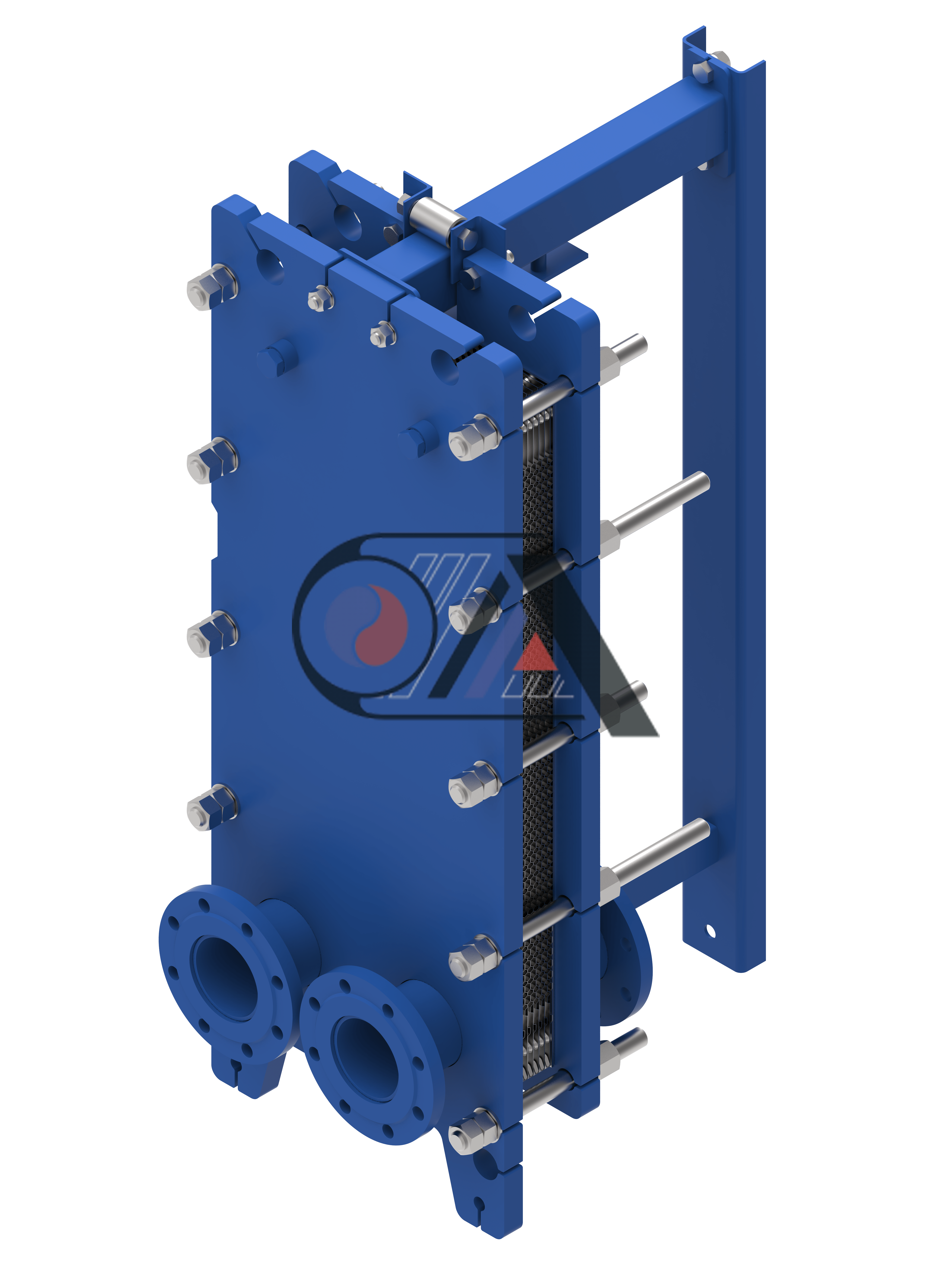

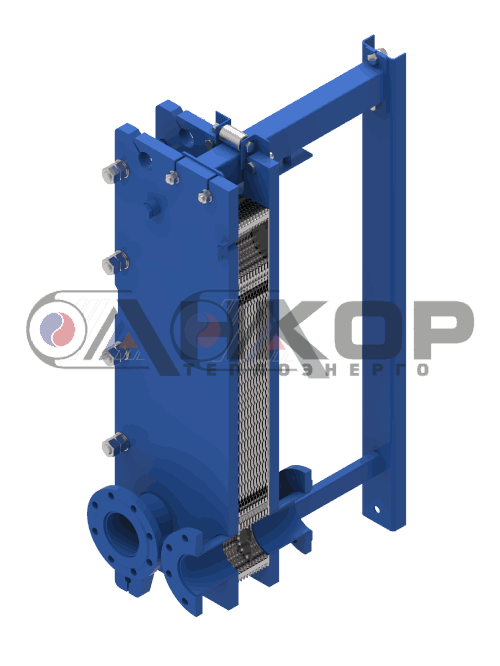

Semi-welded plate heat exchangers

Semi-welded plate heat exchangers are structurally similar to classic gasketed devices. A distinctive feature of this type of equipment is that the channels in one of the working fluids are formed by sections of pairwise welded plates. Due to this, they may be used in corrosive or hazardous fluids where the use of classic gasketed devices with rubber gasket is not allowed.

Since the channels are formed in one cavity of this type of heat exchanger by welding the plates and not by sealing with rubber gaskets, it is able to withstand higher pressures and temperatures of working fluids, compared to the classic gasketed devices.

At the same time, the second cavity of this type of equipment is sealed with rubber gaskets. Accordingly, sections of pairwise welded plates may be disassembled, and they are available for mechanical cleaning of the heat transfer surface.

Semi-gasketed heat exchangers, as well as gasketed devices, imply the possibility of increasing or decreasing the working surface, in the event of a change in the manufacturing process or the need to increase the device capacity. The heat exchanger side along which the channels are formed by the welded sections of plates cannot be cleaned mechanically, however, by applying washing with chemical reagents it is possible to get rid of the main types of impurities.

Technical specifications of semi-welded heat exchanger

| RANGE OF APPLICATION OF GASKETED PLATE HEAT EXCHANGER: | VALUE (CHARACTERISTIC) |

| Maximum operating temperature: | from -30 to +200 °С |

| Maximum pressure: | 2.5 MPa |

| Area range: | from 0,18 to 1800 m² |

| Thermal load | 150 Mw |

| Plate materials: | AISI 304 AISI 316 Hastelloy С-276 SMO 254 Titanium Nickel 200 |

Advantages of a semi-welded plate heat exchanger

Semi-welded heat exchangers, as mentioned earlier, may be used in cases where a gasketed device is not suitable due to the use of rubber seals to seal equipment cavities.

Application of welding to create heat exchanger sections guarantees the reliability and durability of the device.

Semi-welded devices are used in the positions of evaporation of refrigerating agents (most often, the evaporation of ammonia), cooling agents and heating agents of toxic or dangerous substances. Due to the design features, these devices may be much cheaper than other equipment that may be applicable in this position.

Order Online Presentation

Our employee will contact you to coordinate the timing of the presentation

How the price for the semi-welded (semi-gasketed) heat exchanger is calculated

The choice of heat exchange equipment is made individually for each purpose. This also applies to semi-welded heat exchangers.

After receiving the task, the necessary apparatus is chosen. It is made based on the parameters of the manufacturing process that should be ensured, based on the specified costs, temperatures, and other parameters of the working fluids. After determining the device optimal design, the necessary heat transfer area, as well as material performance, the cost of the semi-welded device is determined.

Buying a semi-welded (semi-gasketed) heat exchanger is as simple as a classic gasketed one. You only require to provide data for thermohydraulic calculation and get a technical and commercial offer for a heat exchanger.

Fields of application of the semi-welded heat exchanger

This type of equipment is most in demand in refrigeration equipment, where these devices have proven themselves well. They are found in many enterprises of various industries where deep cooling of raw materials or finished products is required.

Fields of application of the semi-welded heat exchangers:

- Refrigeration supply;

- Chemical industry;

- Metallurgy;

- Oil refining industry;

- Food;

- Fat and oil industry.

Wide-gap heat exchangers