Heat recovery

Utilizer is a device designed to remove heat from combustion products and return it back to the system. Technically, this is the secondary use of energy already received. Recently, it is this type of equipment that is becoming increasingly relevant. After all, energy efficiency and saving of fuel resources are now required in almost every enterprise. Besides, the issue of heat recovery of exhaust gases and similar working fluids also applies to the environmental situation. In recent years, the subject of ecology is generally very often discussed in society, in particular, the problem of emissions of industrial enterprises into the atmosphere. Therefore, such units helping to remove heat from combustion products, saving resources, and at the same time reducing the level of environmental pollution, will be in demand in almost all industries.

How the price for the utilizer is calculated

Flue gas utilizer

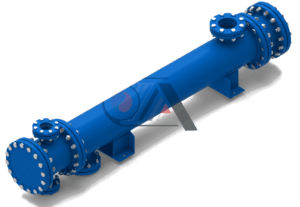

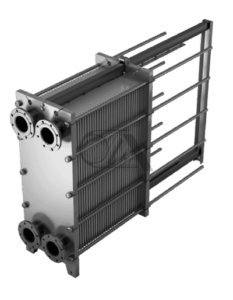

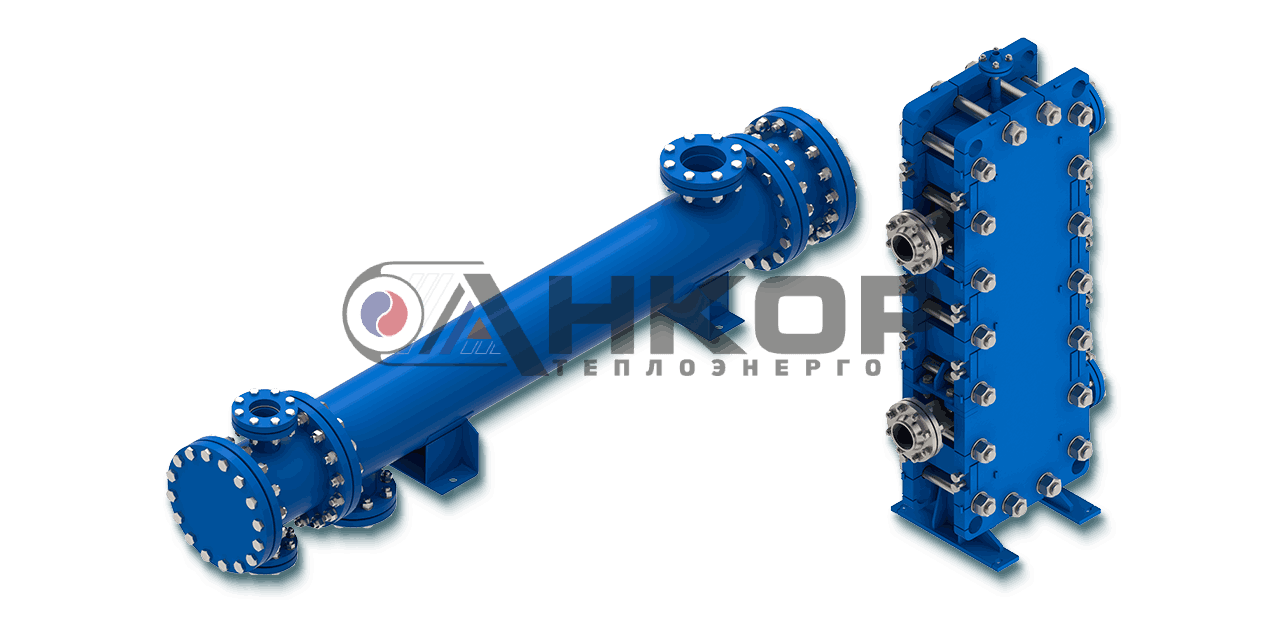

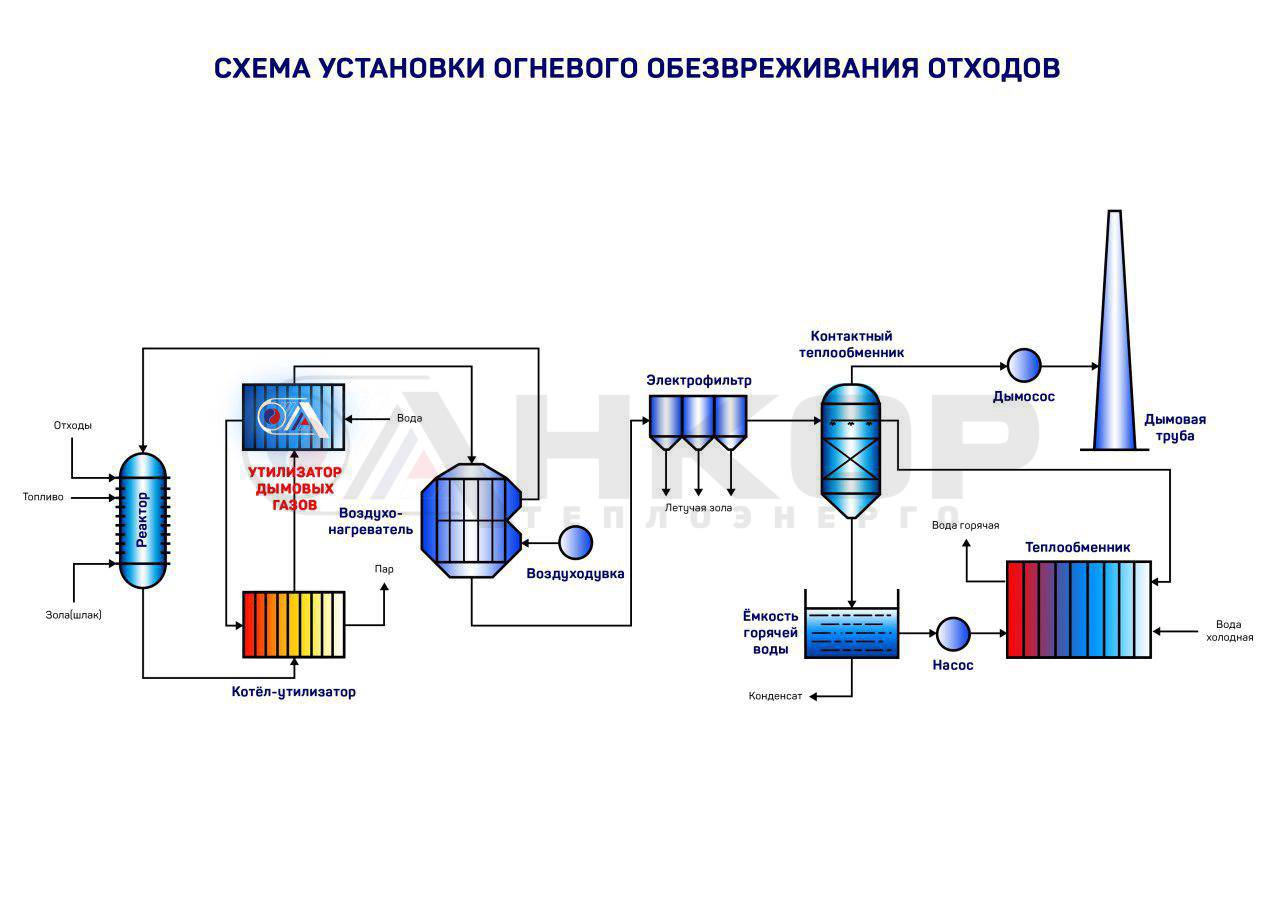

Heat recovery is the main purpose of this type of devices. Typically, energy is utilized from flue gases formed in furnaces after the combustion of natural gas or other fuels. These gases are usually simply emitted into the atmosphere in a large volume, although in this event their temperature can reach 500-600 °C. However, if you install a gas heat utilizer in the line, all this heat may be directed to your own process needs. Often, exhaust gas heat utilizer is used as a water heater. It is also possible to use to heat the premises or to preheat air before it enters the boiler. Such an arrangement will make it possible to save natural gas or other fuel, increase the boiler service life, and improve its efficiency. The most common type of heat exchangers used as a flue gas utilizer will be tube heat exchangers and plate heat exchangers (but with flat plates). For such purposes, it is very important to observe extremely low pressure losses. This is important for the optimal operation of the entire system of gas supply and its further use. Therefore, before installing a gas heat utilizer into the line, it is necessary to calculate first its effect on the installed equipment.

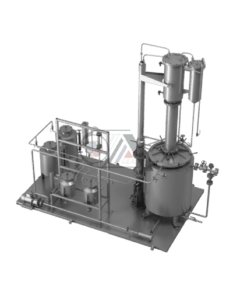

Buy a heat utilizer of petroleum products

In addition to flue gases, it is possible to utilize other gaseous fluids carrying a huge amount of untreated energy. This is primarily a steam utilizer, especially for plants with a large number of boilers and heaters. After all, steam after use as a cooling agent does not have to condense completely and its large volumes simply cannot be used as a result. In the manufacture of various petroleum products, a decent amount of gases is also formed, which may be used further in the production line. Therefore, a heat utilizer of petroleum products is a fairly confident product in our product line. Besides, you can buy the utilizer from the manufacturer, which means that we can take into account any wishes of the customer. This applies both to the type of heat-exchange equipment used, and its dimensions, local sizes, etc.

Utilizer fields of application

Since utilizers are used almost everywhere, since the use of fuel accompanies any manufacture, there is no clear framework for their use.