Oil refining

In a modern market economy, the manufacture of competitive products in the industrial production facilities is directly related to the need for a quick and significant reduction in the energy intensity of manufacturing processes.

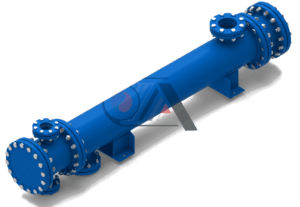

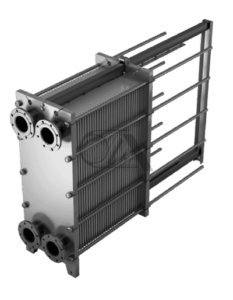

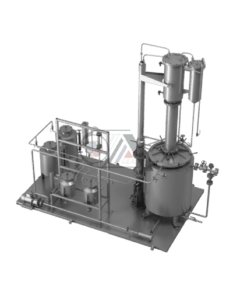

Specialists of Ankor-Teploenergo have developed the design of a plate heat exchanger with a removable shell, which combines a number of process advantages of a gasketed and welded heat exchanger in one compact device. A fully-welded pack of heat exchanger plates, absence of gaskets between the heat exchanger plates, the possibility of access to the device welded pack on the side of one of the working fluids, makes it possible to work with a wide range of contaminated and corrosive fluids at high pressures and temperatures. Compared to the shell-and-tube heat exchangers, a plate heat exchanger, due to the high heat transfer coefficient, makes it possible to reduce significantly the manufacturing sites due to its compact size. Heat exchange equipment may perform the functions of utilizers, condensers, recuperators or boilers for distillation and stripping of the column, and it may also be used at other functional locations.

FUNCTIONAL LOCATIONS:

• Heating of drilling fluids, crude oil and water;

• Utilization of low-grade heat of the industrial water;

• Heat recuperation of diesel and oil flows;

• Heating of oil products and oil;

• Cooling of compressors, diesel plants, industrial solutions;

• Cooling of the liquefied hydrogen gas with recycled water