Spiral heat exchangers

Spiral heat exchangers are made for solving specific problems, in particular, where fluids with solid inclusions or simply very viscous. Such features have provided their niche for this equipment in a number of positions. Moreover, they can be used in a variety of manufacturing facilities.

Spiral heat exchanger technical specification

| The maximum operating temperature:Range of application of welded spiral heat exchangers: | Value (characteristic) |

| Maximum pressure: | up to 1 MPa |

| Maximum operating temperature: | up to 450 ° C |

| Area range: | 1,8 – 120 m2 |

| Channel width: | up to 95 mm. |

| Plate materials: | AISI 316 AISI 316L Hastelloy С-276 SMO 254 Titanium |

Advantages of spiral heat exchangers

1. Operation with contaminated or highly viscous fluids. If we consider spiral heat exchangers, this advantage immediately catches the eye. It can be easily explained by the fact that there are no dead areas in the device channels, they are wide enough, even for large particles of solid inclusions. Therefore, the heat transfer surface is virtually not contaminated. In addition, due to the rather high speeds in channels, they will self-clean.

2. Easy and quick access to spiral. The simplicity and convenience of the design means easy access to both sides for overhaul, flushing and inspection. If you compare plate and spiral heat exchangers, at this point you can see their similarity. This is very actual in cases where mechanical cleaning is necessary.

3. Compactness. Spiral heat exchanger in itself has rather modest dimensions. Accordingly, it requires minimum space for its installation and operation. It is also quite convenient to connect it to the supply pipelines and dismantle it for subsequent service.

4. Efficiency. Despite the lack of corrugation and a fairly wide gap between the spirals, the heat transfer coefficient in the spiral heat exchanger remains at a very decent level and may compete with shell and tube ones. This affects the overall dimensions and heat transfer surface area. Indeed, in today’s market, it is one of the key indicators.

5. Material modification. In order to take into account the specifics of the customer’s manufacturing facilities, ensure the correct life, and based on the technical specifications of the spiral heat exchangers, we will choose the most optimal materials. There is a possibility of manufacturing spirals from stainless steels, nickel alloys, titanium.

Order Online Presentation

Our employee will contact you to coordinate the timing of the presentation

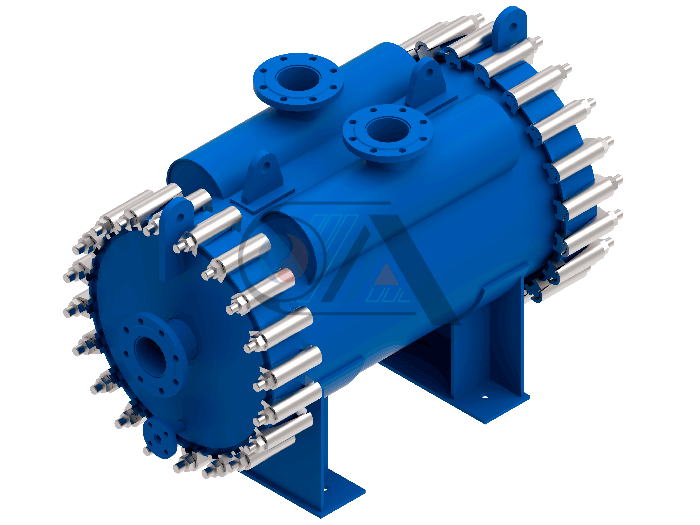

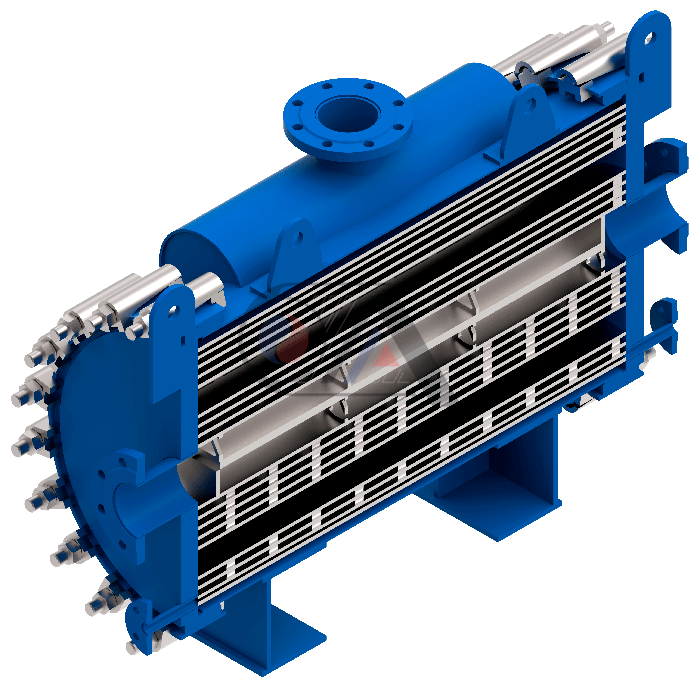

Arrangement of the spiral heat exchanger.

The design of spiral heat exchanger consists of two sheets bent in a spiral forming two types of channels. At the same time, they have a rectangular cross section, which facilitates the movement of working fluid along them. To prevent the channels from deforming, pins are provided on one side of the sheet to prevent shape changes. The formed channels are welded on one side to avoid product leakage. The spirals themselves are placed in casing and welded to it.

How the price for the spiral heat exchanger is calculated

For spiral heat exchangers, the price is calculated according to the following indicators: all the material necessary for product manufacture, labour costs for their manufacture, delivery and packaging are evaluated. All this is selected when calculating the purpose for the product. An important role is played by the material design of spirals, shell, and other components. Based on these data, the total cost is calculated.

Fields of application of the spiral heat exchanger

• Oil industry – it is used with highly viscous media such as heavy oils, fuel oils.

• Sugar and food industry – sunflower oil, raw juice, mayonnaise, ketchup, mash

• Pulp and paper industry – waste solutions of sulfates, drain water and waste water.

• Chemical industry – acetyacrylate, MEA, MDEA, PVC

• Pharmacy