Metallurgy

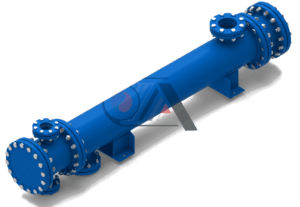

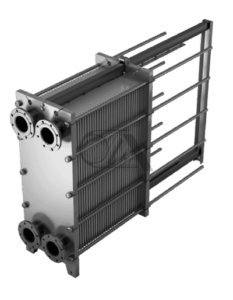

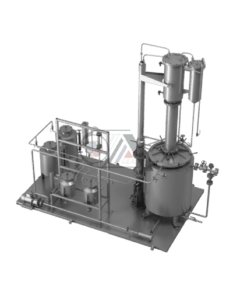

Plate heat exchangers manufactured by Ankor-Teploenergo are widely used in steel rolling systems, blast furnace cooling systems, and other various steel-casting processes.

The constantly growing global competition in the metallurgical industry forces the metallurgical industries to look for ways to reduce the cost of manufacture. Metallurgy is one of the most energy-intensive industries in the national economy. For example, the share of costs for fuel and energy resources in the total production costs of ferrous metallurgy enterprises reaches 30% and is constantly growing due to the increase of prices for fuel and energy resources. Therefore, increasing the efficiency of the use of fuel and energy resources at the moment is one of the priority tasks for the specialists of metallurgical plants. The performed studies prove that one of the ways to solve this problem is heat recovery.

The use of Ankor-Teploenergo heat-exchanging equipment makes it possible to solve effectively the heat transfer problems at the enterprises of the metallurgical industry.

FUNCTIONAL LOCATIONS:

• Cooling of oils, casting molds, emulsions of rolling mills;

• Utilization of industrial heat;

• Cooling of continuous steel casting plants;

• Compressor cooling;

• Cooling of coke oven batteries, coke oven gas;

• Chemical processing of coking products.