Brazed plate heat exchangers

Brazed heat exchangers are high-performance heat exchangers aimed at solving various problems. They are a subtype of plate heat exchangers. They were widely used in the HVAC sector, as freon evaporators in refrigeration, in the oil and fat industry, and many others.

Technical characteristics of the brazed heat exchanger

| Application range of welded and plate heat exchangers: | Value (characteristic) |

| Power range: | from 2 to 2500 kW |

| The maximum pressure: | 45 bar |

| The temperature range of application: | from -85 to 250 ° C |

| Plate materials: | AISI 316, AISI 304, etc. |

| Solder material: | stainless steel and brass |

Advantages of brazed heat exchangers

1. Efficiency – If you describe the brazed plate heat exchangers in one word, it will be this. Their entire design is aimed at achieving the most productive area with minimal financial costs. This is due to very strong turbulence of flows due to the geometry of plates and low corrugations. At the same time, relevance to cases with small temperature differences is not lost.

2. Fields of application. The absence of rubber gaskets in the presence of welds allows using a brazed plate heat exchanger for tasks with corrosive or hazardous fluids. Indeed, in this case, it is necessary to avoid possible leakage of substances, which is impossible in the devices without welds.

3. Operating parameters. The brazed heat exchanger may be used at positions where the pressure may reach 45 bar. The maximum operating temperature is 250 °C.

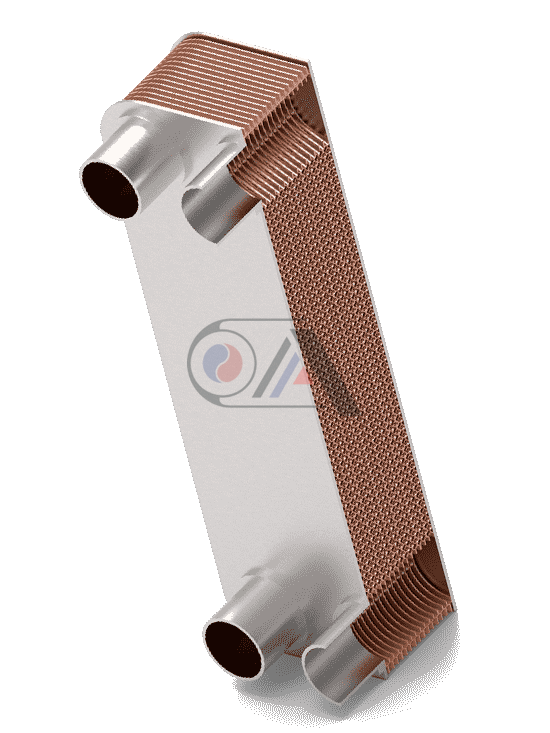

4. Compactness. A brazed heat exchanger takes up much less space when compared with other types of equipment. This is primarily ensured by high efficiency. If we compare the same positions, it can be hugely smaller than the shell-and-tube one, and several times smaller than gasketed one.

5. Self-cleaning effect. Due to the low height of corrugations, removal of contaminants from the plate surface should be carried out directly during operation. This is due to the high degree of turbulization of flows. Because of this, deposits are washed off by the working fluid itself.

6. Reliability. Brazed plate heat exchanger has a very long service life – more than 5 years. Under the right conditions of use, it can be about 10-15 years. In addition, the design excludes possibility of leaks and overflows.

7. Delivery period. Low material consumption makes it possible to manufacture the brazed heat exchangers within a very short period. And the geographical location of our company will greatly simplify delivery.

8. A large range of products. A variety of plates and designs makes it possible to choose the most optimal equipment. All customer requirements are also taken into account. There is the possibility of manufacturing from various materials and alloys.

Order Online Presentation

Our employee will contact you to coordinate the timing of the presentation

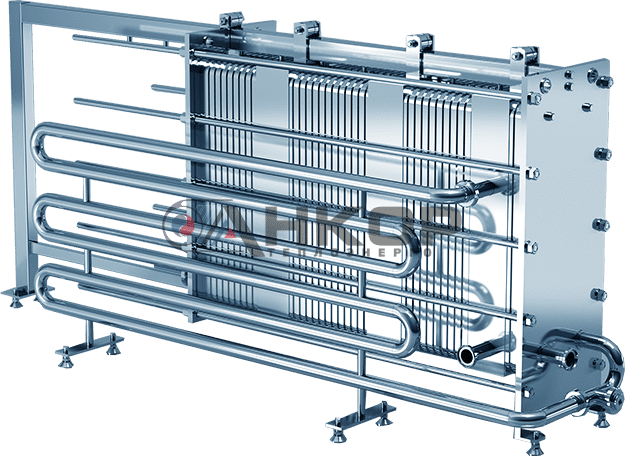

Arrangement of the brazed heat exchanger

Brazed heat exchanger has a quite standard design. A pack of plates welded together around the perimeter. Copper is commonly used as solder. In some cases, stainless steel. The pack is placed between shell plates, which excludes the possibility of leaks. Delivery of working fluids is carried out through the hardware connections.

How the price for the brazed heat exchanger is calculated

After the calculation and selection of equipment, based on customer’s inputs, the cost is calculated. It depends on the material performance, thickness of shell plates, variations of joints. And given the low material consumption and low labour costs in production, the cost of such a product as brazed plate heat exchanger will be calculated as soon as possible.

Fields of application of the brazed heat exchangers

HVAC – they are used for heating and hot water supply, ventilation, under floor heating. Considering that a heat exchanger of very low heat duty may be often required for these purposes, the compactness and low cost will be a significant advantage over other types of devices.

Refrigeration equipment – freon evaporators and condensers, glycol coolers for refrigerators. The design allows avoiding leaks of freon, which is a hazardous fluid, which makes the use of this type of equipment highly relevant.

Fat-and-oil – final oil coolers, steam oil heaters. In such cases, the fluids does not require constant cleaning and the use of a brazed heat exchanger is quite justified.

Chemistry – as condensers or coolers for alcohols, this type of equipment will also be relevant.